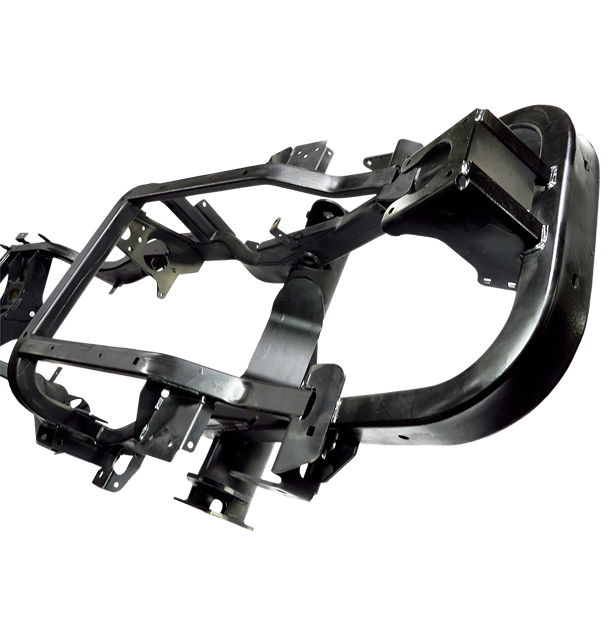

Precision tube bending without the delays or do-overs

Do you have tight timelines and tighter tolerances? Bauer delivers high-accuracy tube bends that always meet your specs and deadlines, keeping even your most complex projects on schedule.

Industry leaders trust Bauer’s tube bending & welding

Fabrication failures slow everything down

Misquotes. Long lead times. Sloppy welds. Poor fits. If you’ve worked with the wrong tube supplier before, you know how costly it can be.

Slow quotes lose work

Sometimes speed is everything. That’s why you can expect rapid responses within one business day, so we can get to work fast.

Limited capabilities waste time

Don’t risk working with companies that outsource critical processes to third-party vendors you don’t know or trust. Bring bending, forming and robotic welding under one roof with one team, one timeline.

Inconsistent bending adds cost and delays

Every misaligned tube causes rework or redesign. With the proper DFM preparation, we hit your specs the first time and keep tolerances tight through the thousandth.

From prototype to production, we make fabrication easy

Our integrated tube fabrication services deliver speed, consistency and cost-efficiency at every step.

In-house fixture design for faster ramp-up

Wide material support: steel, stainless, aluminum, copper, chromoly

Bending, forming, MIG/TIG/robotic welding and more

Built for product launches

Start projects faster and more affordably with Bauer’s in-house fixturing, tooling and bend die inventory.

In-house fixture design for faster ramp-up

Massive bend die library reduces tooling costs

Robotic welding ensures consistency and throughput

Engineering collaboration included

We don’t just build from your file and hope for the best. We help you make it better and won’t fabricate anything until designs are ready. Simplify manufacturing and solve pre-production problems with expert DFM for tube designs.

Design for manufacturability (DFM) feedback

Tolerancing and material guidance

Collaborative quoting with redline support

Why product teams count on us.

These engineers and buyers faced tight deadlines, tough specs and last-minute changes. Hear how Bauer helped them deliver.

“With them being able to give me the quote back really fast, it helps streamline the prototyping process so we could get it out the door faster.”

Brad Merola

Engineering program manager, American Expedition Vehicles (AEV)

“Bauer has overall fantastic service, and I like working with the team. You don’t want to work with someone you don’t like. So, it’s extremely important to develop a strong relationship.”

Stephen Duley

Commodity manager, Generac Power Systems

“Bauer does a nice job with being upfront. If there’s any exceptions or they’re suggesting an alternative material or they’re requesting additional tolerance on something, they’re making sure they do their front-end work, which is good to see.”

Alex Nelson

Procurement manager, SICO

Pricing factors

Piece count

Larger runs (500+) unlock better pricing. We support prototyping as well and can help you find cost efficiencies all the way to full production.

Part complexity

The number of bends, welds and operations in your process affects time and cost. Adding chrome, e-coat, powder coat, primer, paint and/or corrosion protection will affect turnaround times.

Material and finish

Mild steel is often a cost-effective option. Selecting stainless steel, aluminum or adding coatings like zinc can improve performance but may increase costs.

Tooling needs

You can reduce or remove your tooling costs with our in-house tooling library. Custom tooling or unique fixturing for specialty parts may impact your quote.

The Bauer three step process

1.

Submit your part design

Bauer’s estimators provide quick, detailed feedback and manufacturability guidance.

2.

Consolidate your production

Get complex bends and robotic welds from one trusted tube fabrication source.

3.

Launch with confidence

Reduce delays, control cost and eliminate surprises with reliable vendor support.

Capabilities Overview

Tube diameters of 1/2” to 5”

Round, square and rectangular tubing

Multiple materials

Stainless steel, carbon steel, aluminum and copper

Welding

MIG, TIG, robotic and spot welding

Tolerances

Bend tolerances as close as 0.006”

Etching & labeling

Marking options include QR codes and part numbers

PPAP support and customer-specific QA requirements

Ideal for OEMs and production-critical parts

FAQs

If you don’t see your question answered here, just reach out. Our team is always happy to help.

We quote quickly and turn most jobs around faster than industry average.

Yes, we build parts for prototyping, pilot runs and full-scale production.

We prefer STEP or 3D CAD files but can work with most common formats.

Absolutely. Our team provides feedback to reduce cost and improve manufacturability.

Yes, reach out and ask about our customer inventory programs.

There’s no time like now

Ready to get your tube design quoted and optimized?

Reach out and we will get back to you within 24 hours to discuss your project. Then you’ll receive an expert quote with initial DFM insights within three to five days. We work quickly because we know some projects can’t wait. And don’t worry, we never spam your inbox or sell your information.